Where imagination meets innovation: Championing your success

Champion Aeromotive is a specialized provider of design, engineering, and manufacturing services for the automotive, transportation, defense, and entertainment industries. Our team of experienced professionals is dedicated to delivering innovative, high-quality solutions that meet the unique needs of our clients.

We leverage the latest technology and industry best practices to provide comprehensive capabilities across the entire product lifecycle, from initial concept to final assembly. Whether you need assistance with design ideation, engineering analysis, or manufacturing processes, we have the expertise and resources to bring your vision to life.

Process Specific Capabilities

Transportation

Defense

Entertainment

Capabilities

01

01 step

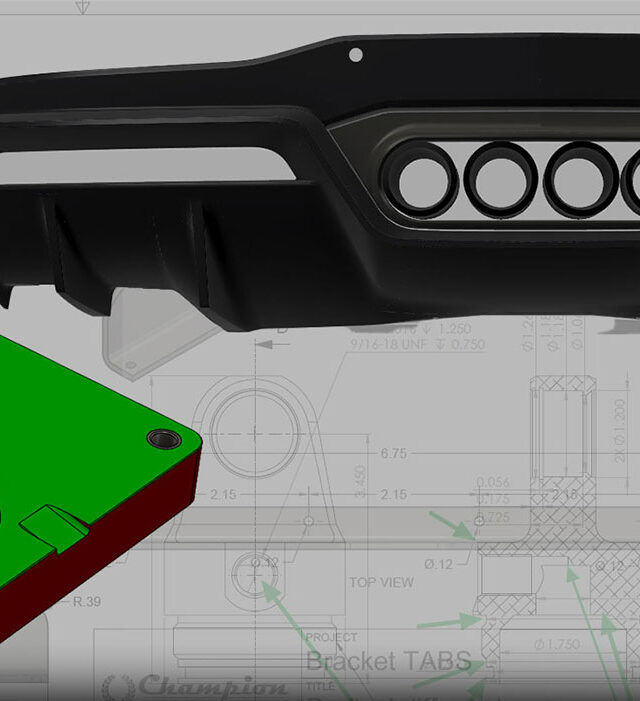

Design

Using CAD, CAM, Catia and Autodesk, we can turn your ideas into manufacturable designs, while optimizing for efficiency and cost-effectiveness. Our expertise in process design and prototype fabrication allows us to quickly iterate and refine designs, while our reverse engineering capabilities allow us to improve upon existing products.

02

02 step

Tooling

We specialize in the design and build of tooling, molds, jigs and fixtures for advanced composites processing or RIM Molding.

03

03 step

Manufacturing

We offer a wide range of manufacturing capabilities including additive manufacturing, composites manufacturing, RIM manufacturing, CNC machining manufacturing, tooling and mold manufacturing, and final assembly services.

Specialized Molding Capabilities for your specific project

CapabilitiesEquipment List

Our state-of-the-art equipment list includes 5-axis robotic CNC machines, hydraulic forming presses, and urethane injection systems for both low and high-pressure applications.

Our curing ovens are equipped with programmable controls and vacuum ports for precision control. Additionally, we offer welding services utilizing TIG, MIG, and plasma torch systems. With CAD/CAM software such as CATIA, Solidworks, and Autodesk Fusion 360, we are able to design and fabricate parts with precision and accuracy. Our comprehensive equipment list also includes a drive-in spray booth, grinding booth, and fabrication tables.

- 5-Axis Robotic CNC

- 3-Axis CNC Router

- Curing Oven w/ programmable controls, data logging, vacuum ports

- Hydraulic Forming Presses (5)

- Heated Platen system

- High Pressure Krauss Maffei RIM System

- Mold Chiller and Heating

- Grinding Booth for Trimming

- Drive-in Spray Booth

- TIG Welding System

- MIG Welding System

- Plasma Torch

- CATIA Modeling

- Autodesk Fusion 360

- Rhino 3D

- Solidworks

- Autodesk Powermill